Precision and Reliability in machinery

Machinery thrives on precision. Without precise components, even the strongest equipment falters. LM slide bearings have become essential for enhancing performance across multiple industries. Known in Thailand as LM slide bearing (ลูกปืนสไลด์ lm, which is the term in Thai), this component ensures machinery operates smoothly, quietly, and with minimal maintenance.

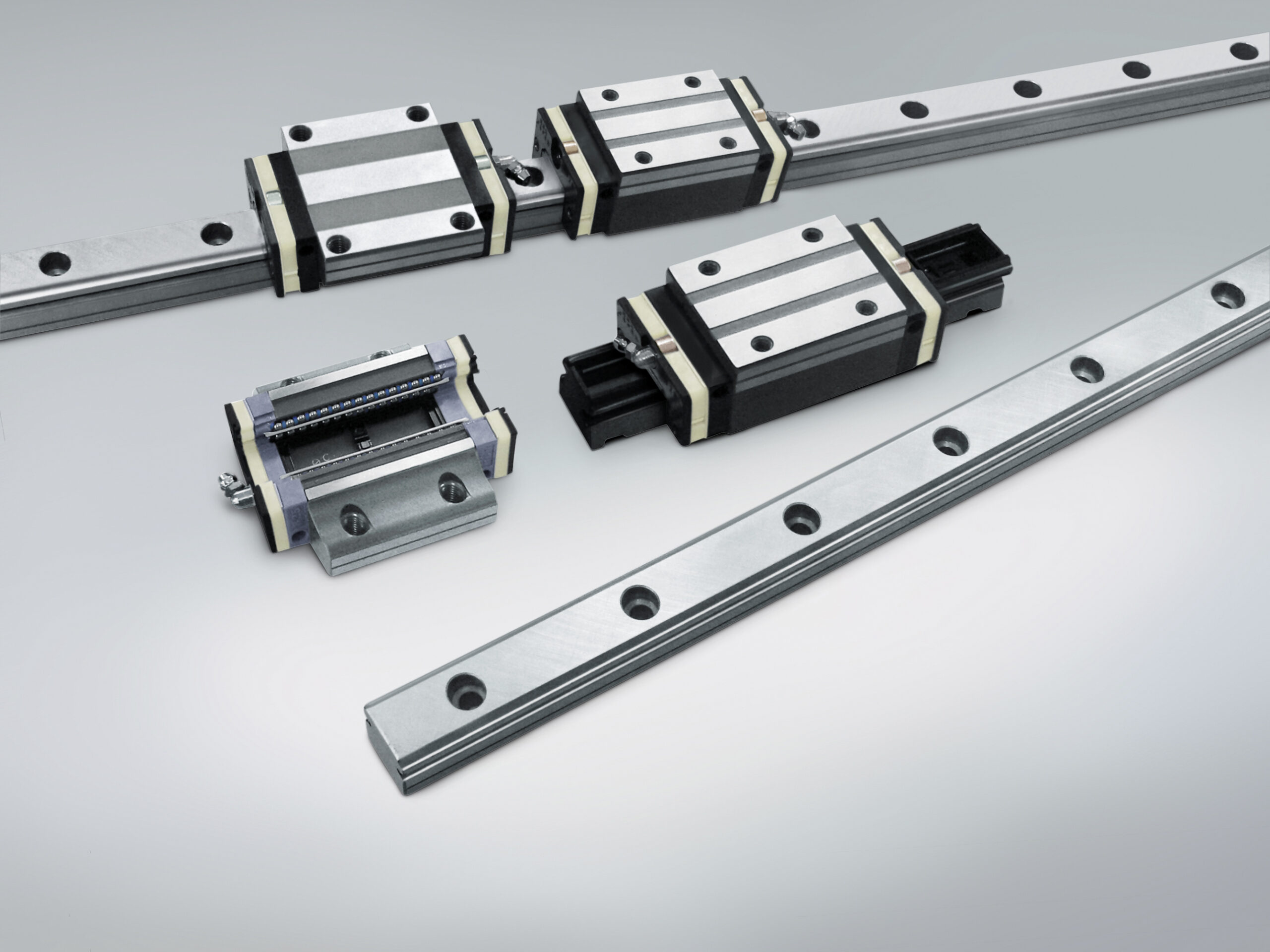

Understanding the Mechanics of LM Slide Bearings

At their core, LM slide bearings facilitate linear motion with minimal friction. Unlike conventional bearings, these bearings consist of meticulously aligned balls moving effortlessly along a track. This design results in smoother, more reliable movements. It reduces wear, increases durability, and significantly lowers noise.

Here are some primary advantages of LM slide bearings:

- Reduced friction: Enhances efficiency and lowers energy consumption.

- High precision: Supports consistent, accurate movements critical for automation.

- Longer lifespan: Minimal wear means reduced downtime and maintenance costs.

- Quiet operation: Essential for environments sensitive to noise.

Applications Across Industries

The versatility of LM slide bearings places them at the heart of numerous sectors. From automotive manufacturing to medical devices, these bearings ensure consistent performance. CNC machines rely heavily on their precision for crafting intricate parts. Similarly, robotics and automation depend on their reliability for seamless, accurate motions.

Industries that particularly benefit from LM slide bearings include:

- Automotive: Steering systems, seat adjustments, and manufacturing equipment.

- Aerospace: Precision assembly tools and flight control systems.

- Healthcare: Surgical robotics and diagnostic equipment.

- Manufacturing: Industrial robots, conveyors, and packaging lines.

Maintenance Made Easy

Proper maintenance prolongs the effectiveness of LM slide bearings. Fortunately, upkeep is straightforward. Regular lubrication prevents friction build-up and maintains smooth operation. Additionally, periodic inspections ensure bearings remain in optimal condition. This simplicity translates into lower overall maintenance costs, making LM slide bearings highly economical.

Key maintenance tips include:

- Routine lubrication: Use quality lubricants suitable for your machinery type.

- Regular inspections: Check for signs of wear or contamination.

- Alignment checks: Ensure proper alignment to avoid premature bearing failure.

Enhancing Productivity with LM Slide Bearings

Efficiency and reliability directly impact productivity. Implementing LM slide bearings reduces machinery downtime and boosts overall output. Their consistent performance ensures production lines keep moving without unexpected interruptions. Businesses benefit from lower operational costs and higher-quality outputs.

Selecting the Right LM Slide Bearings

Choosing the correct bearings involves several considerations:

- Load capacity: Ensure the bearing matches the machinery’s maximum load.

- Speed requirements: Match bearings designed for high-speed or low-speed applications.

- Operating environment: Select corrosion-resistant materials for harsh conditions.

By choosing wisely, businesses enhance the reliability and longevity of their machinery.

Conclusion: Investing in Quality

LM slide bearings offer undeniable advantages in machinery applications. Their precision, durability, and ease of maintenance provide substantial returns on investment. By reducing downtime and increasing operational efficiency, these bearings are not merely an addition but an essential component for businesses aiming for excellence.